Ultraviolet radiation and its application in air conditioning

In this article, Dannenge International’s technical director, Ricardo Cherem de Abreu, clarifies about ultraviolet radiation, its effects, application in air conditioning and photocatalytic technologies (PHI), a topic currently in vogue in the face of the pandemic by COVID-19. Abreu warns of the substantial differences between the processes of direct irradiation of surfaces (UVGI) and photocatalysis (PHI), important information when making a decision to invest in these technologies in order to improve health safety in environments air-conditioned.

Good reading!

Ultraviolet radiation and its application in air conditioning

The effects of ultraviolet radiation on nature are well known, just remember that where the sun rays hit, there is no proliferation of fungi and bacteria. Ultraviolet radiation is currently applied in air conditioning systems in two completely different ways: direct surface irradiation and photocatalytic oxidation. This article aims to explain concisely these two applications.

Ultraviolet germicide light (UVGI)

The germicidal action of ultraviolet irradiation has been known and applied for over a century. The radiation range with wavelength between 200 and 300 nm, known as UV-C, is very efficient in killing fungi, bacteria and molds, as well as disabling virus, since applied at the appropriate dosage, remembering that dosage is dependent on exposure time and radiation intensity.

An important aspect of ultraviolet radiation is that it is harmful to humans, causing burns to the skin, ocular cornea and retina. For this reason, exposure to UV radiation should be avoided, and many countries have legislation prohibiting direct exposure to ultraviolet light.

Germicidal ultraviolet light (UVGI) is applied in air conditioning systems for surface disinfection, finding greater application in the cleaning and protection of coils. Its use as an air purifier is limited by the high speeds adopted in ducts, which requires high-power irradiation to ensure its effectiveness, or even stretches of large-length ducts equipped with UV-C lamps. It is important to take into account that UVGI only eliminates microorganisms that pass through its light, acting as a filter, that is, it serves to decrease the background concentration of contaminants in occupied rooms.

An interesting analogy is to imagine that we are working with localized sinks of contaminants, which would be the return openings, through which the air of the room is aspirated to be led to the “air purifier”.

Because it is a well-known technology and on which there is applicable standardization, although exclusively for surface protection, it is being recommended as a solution for air purification in the built environment.

Photocatalytic Oxidation – (PCO)

Ultraviolet light from the sun’s rays, when hitting certain metal oxides on the soil, ionizes water vapor and oxygen molecules, which unite in hydrogen peroxide. Hydrogen peroxide is highly reactive and one of the best-known germicides.

In nature hydrogen peroxide is found in concentrations ranging from 0 to 50 ppb (0 to 0.05 ppm) and, the higher its concentration, the cleaner the site is, due to the oxidative potential of peroxide, which reacts with organic and inorganic gases, kills fungi and bacteria, as well as disables viruses in suspension in the air or on surfaces. This phenomenon is known as photocatalytic oxidation (PCO) and replicated in equipment, has been successfully applied for over thirty years in the purification of enclosed environments.

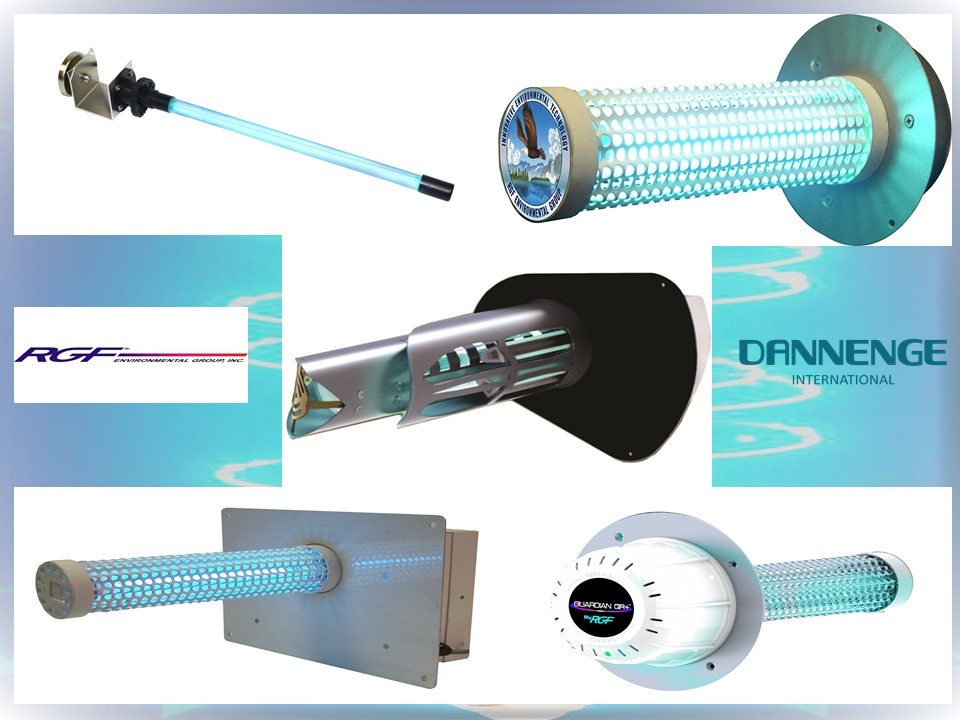

RGF Environmental air purifiers, which use photocatalytic oxidation in their own patented process, Photo Hydro Ionization (PHI) are sized to ensure concentrations of 20 to 50 ppb in the treated environment, simulating the best natural conditions. All favorable results of efficacy tests performed so far had this concentration level as a minimum.

Going back to the previous analogy, it would be like we had spread throughout the built environment a multitude of sinkholes. It is the only way to effectively hinder the path of aerial transmission, in addition to the use of personal protective equipment, such as face protection masks.

It is important to remember that multicellular beings have natural protection against hydrogen peroxide. At normal concentrations, it does not hurt us. For instance, the limit value of hydrogen peroxide concentration admitted for work occupation in a daily basis is 1000 ppb, i.e., twenty times higher than the highest desired concentration. Furthermore, the concentration limit above which health damage can be expected is 75,000 ppb. A long way from those concentrations we are talking about.

The substantial differences between ultraviolet germicidal light irradiation (UVGI) and photocatalytic oxidation (PCO – PHI) processes were presented. This is relevant information when making a decision on investing in these technologies in order to improve health safety in air-conditioned, or closed, environments.